| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

- Iso 2768 Mk Tolerance Table Pdf

- Iso 2768 Mk Tolerance Table Saw

- Iso 2768-mh Tolerance Chart

- Iso 2768 Mk Tolerance Table

- Iso 2768-mh Tolerance Table

Iso 2768 Mk Tolerance Table Pdf

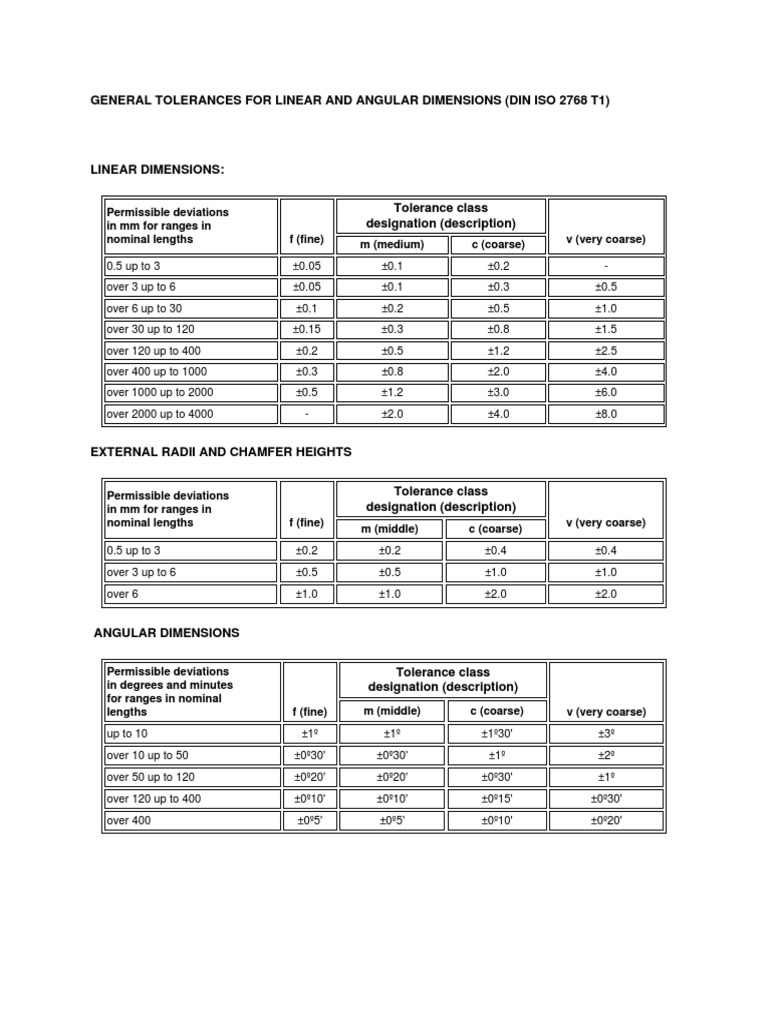

Table 6: General tolerances for symmetry (DIN ISO 2768 T2) The general tolerance for run-out and concentricity for class »K« is 0.2mm. In special cases for shape and position it is possible to choose tolerance class »H«. The general tolerance for run-out and concentricity for class »H« is 0.1mm. Mechanical Tolerance Chart Data. The following Engineering calculator will show the plus and minus tolerance for the specific ISO 286 Shaft tolerance data. Enter your desired preferred tolerance grade and the nomial size. Also see Table of Hole Tolerances per. Preferred tolerance grade ISO 286; International Tolerance Grades. General tolerance ISO 2768 does not specify where to use these tolerances. As per design requirements and manufacturing capability tolerance class is defined. For example: For sheet metal parts ISO 2768–mk is used. And for machined components ISO 2768–fh can be used. By the way, DIN 2768mk is a general tolerance table that provides the tolerances for anything that is not toleranced on the drawing, it does not refer to the diameter tolerances you are asking about. You can find info on the DIN 2768 at the link below. Split Cotter Pins (DIN 94 / ISO 1234) Circlips - Internal (DIN 472) Circlips - External (DIN 471) ISO Tolerances for Shafts (ISO 286-2) ISO Tolerances for Holes(ISO 286-2) Example limits and fits using hole basis; Machining Process Associated with IT Tolerance Grade; ISO Hole and Shaft Tolerance Band; Table of Typical Surface Hardness Values.

- Angular Dimension

- External Radius and Chamfer height

- Geometric Tolerance such as straightness, flatness, perpendicularity, symmetry and runout.

General Tolerance : ISO 2768

Linear DimensionsNominal Length Range in mmTolerance Classf(fine)m

(Medium)c

(coarse)v

(very coarse)0.5 up to 3±0.05±0.1±0.2-3 up to 6±0.05±0.1±0.3±0.53 up to 30±0.1±0.2±0.5±130 up to 120±0.15±0.3±0.8±1.5120 up to 400±0.2±0.5±1.2±2.5400 up to 1000±0.3±0.8±2.0±4.01000 up to 2000±0.5±1.2±3.0±6.02000 up to 4000-±2.0±4.0±8.0External Radius and Chamfer HeightsNominal Length Range in mmTolerance Classf

(fine)m

(Medium)c

(coarse)v

(very coarse)0.5 up to 3±0.2±0.2±0.4±0.4over 3 up to 6±0.5±0.5±1.0±1.0over 6±1.0±1.0±2.0±2.0Angular DimensionsNominal Length Range in mmTolerance Classf

Iso 2768 Mk Tolerance Table Saw

(fine)m(Medium)c

(coarse)v

(very coarse)up to 10±1°±1°±1°30'±3°over 10 up to 50±0°30'±0°30'±1°±2°over 50 up to 120±0°20'±0°20'±0°30'±1°over 120 up to 400±0°10'±0°10'±0°15'±0°30'over 400±0°50'±0°50'±0°10'±0°20'Straightness and FlatnessNominal Length Range in mmTolerance ClassHKLup to 100.020.050.1over 10 up to 300.050.10.2over 30 up to 1000.10.20.4over 100 up to 3000.20.40.8over 300 up to 10000.30.61.2over 1000 up to 30000.40.81.6PerpendicularityNominal Length Range in mmTolerance ClassHKLup to 1000.20.40.6over 100 up to 3000.30.61over 300 up to 10000.40.81.5over 1000 up to 30000.50.82SymmetryNominal Length Range in mm

Iso 2768-mh Tolerance Chart

Tolerance ClassHKLup to 1000.50.60.6over 100 up to 3000.50.61over 300 up to 10000.50.81.5over 1000 up to 30000.512RunoutHKL0.10.20.5

Tolerance ClassHKLup to 1000.50.60.6over 100 up to 3000.50.61over 300 up to 10000.50.81.5over 1000 up to 30000.512RunoutHKL0.10.20.5Iso 2768 Mk Tolerance Table

Iso 2768-mh Tolerance Table

Read this article for details on Limit Fit and Tolerance.